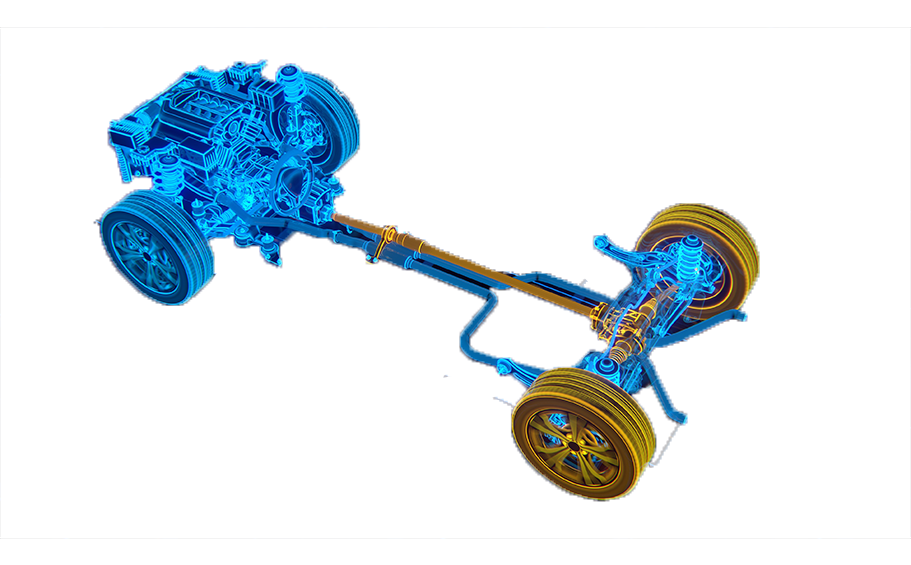

All major structural failures in Automotive systems are attributed to Fatigue loading. Failure due to Fatigue will result in delay of product launch, product recalls, warranty claims and legal liabilities.

Xitadel’s domain expertise in defect characterization, crack initiation and propagation, long-term performance prediction while considering manufacturing and operating conditions. We offer rapid and robust solutions for improving product reliability.

Fitness of the structure to perform its intended functions throughout its predicted lifetime is an important attribute of Structural Integrity Analysis.

Xitadel has in-depth knowledge in analysis of system level Structural Integrity to comply with operating conditions, regulatory requirements and product performance targets .

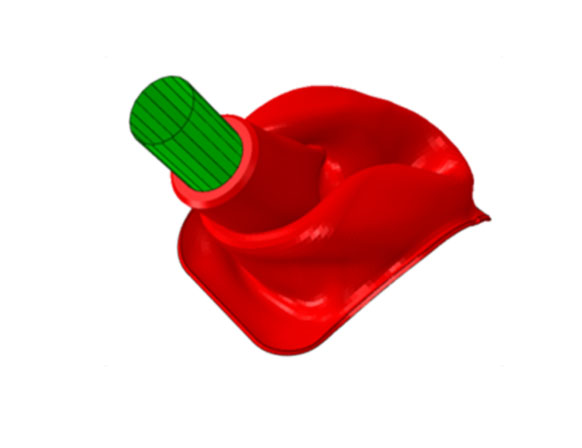

Material data from suppliers may not have sufficient material property details for simulation. Approximating the material model can have an adverse effect on the outcome of simulation. Xitadel uses optimization techniques to derive complex material properties for virtual simulation that matches the experimental test data.

Strength assessment is important for any design and this involves virtual testing & validation before manufacturing and product release. Xitadel has expertise in System, Sub-system and Component level Structural Strength validation using coupled Multiphysics simulation to improve product reliability and quality.

Crack initiation and Failure is a complex phenomenon based on material types and manufacturing considerations. Xitadel has expertise in analysing progressive damage and failure for different material types including ductile, brittle, composites and can predict the crack initiation and subsequent failure.

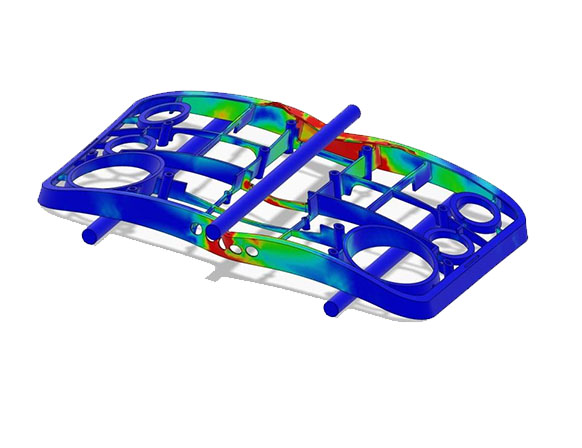

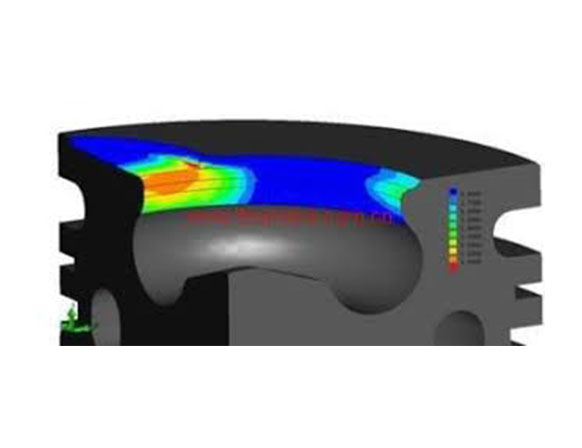

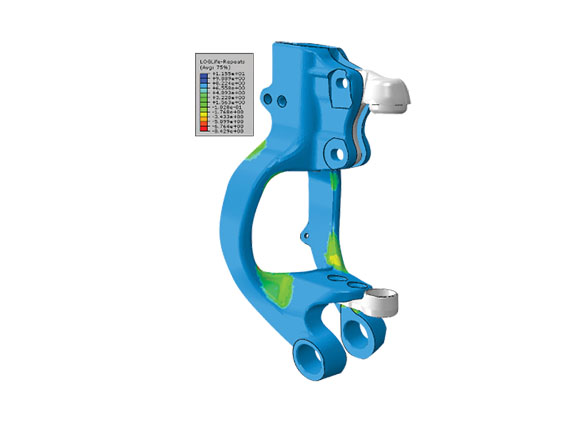

The Stress or Strain based fatigue enables calculation of fatigue life at every point of the entire model, based on surface finishes, material properties and operating conditions. Xitadel helps customers to calibrate the input fatigue curve from Vehicle Dynamics Simulation using road load data and vehicle parameters.

The stresses induced due to vibration and subsequent fatigue failure in nonlinear materials is the challenge faced by designers today. Xitadel provides comprehensive Fatigue analysis which includes Power Spectral Density (PSD) of loads and super-imposing multiaxial PSD with critical plane analysis. This allows for the validation of design for fatigue and avoids over-engineering due to the uncertainty of fatigue life.

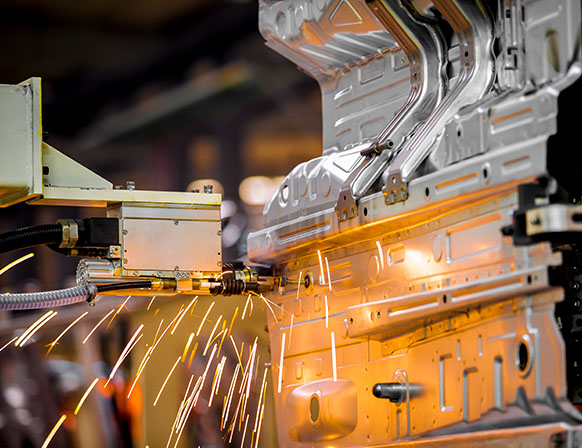

Weld Fatigue is a complex phenomenon. Calculation of fatigue life becomes a difficult task that often results in poor correlation with test data. Xitadel’s knowledge in Weld Fatigue helps customers perform fatigue assessment of the welded structure in accordance with BS7608 standards.

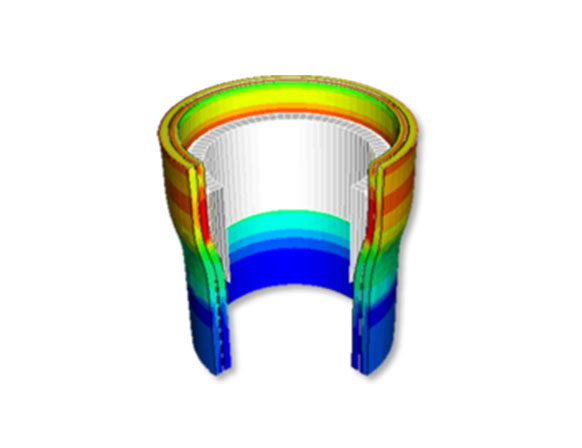

Fatigue loading due to dynamic operating conditions is a complex phenomenon and often results in failures and subsequent warranty costs. The method of evaluating fatigue life using manual spreadsheets is obsolete, time consuming and inaccurate.

Xitadel provides comprehensive fatigue life evaluation for low or high cycle fatigue for different material properties, surface finishes and operating conditions using Stress or Strain based approach.

As a trusted partner, you can depend on Xitadel to provide outstanding value to your organization in all areas of World Class Technology, Expertise and Consulting.